- Tel:0086-519-83783531

- cel:0086-13961177625

- E-mail:jianglijing1022@126.com

- add:cheng zhang Jia zeTown Wujin District, Changzhou City, Jiangsu Province

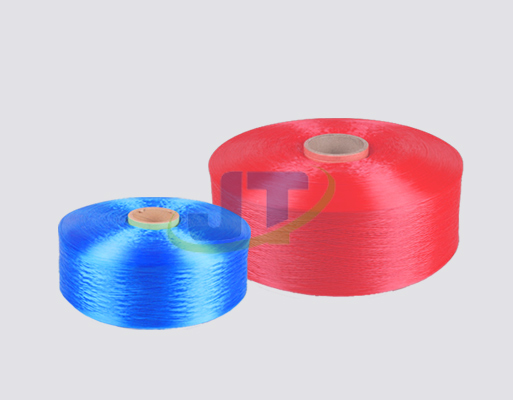

There are many types of chemical fibers used in textiles. FDY polypropylene yarn is one of them. What material is it made of? How is it different from traditional chemical fibers? Let's take a look at the jacket materials it uses.

The varieties of polypropylene fibers include filaments, including undeformed filaments and bulky textured filaments, short fibers, bristles, split membrane fibers, hollow fibers, special-shaped fibers, various composite fibers and non-woven fabrics. The main purpose is to make carpets (including carpet base cloth and suede), decorative cloth, furniture cloth, various ropes, strips, fishing nets, linoleum, construction reinforcement materials, packaging materials and industrial cloths, such as filter cloth and bag cloth Wait. In addition, the application in clothing is becoming more and more extensive. It can be blended with a variety of fibers to make different types of blended fabrics. After knitting, it can be made into shirts, outerwear, sportswear, socks, etc. The quilt made of polypropylene hollow fiber is light, warm and elastic. Polypropylene industrial filter cloth Polypropylene does not contain chemical groups that can bind to dyes in its macromolecular structure, so it is difficult to dye. The scientific name is polypropylene fiber. It melts near the flame and is flammable. It burns slowly and emits black smoke from the fire. The upper end of the flame is yellow and the lower end is blue, emitting a smell of petroleum. After burning, the ashes are hard round and light yellow-brown particles, which are easily broken by hand twist. . Usually, the melt coloring method is adopted, the pigment preparation and the polypropylene polymer are uniformly mixed in a screw extruder, and the color fastness of the colored fiber obtained by the melt spinning is very high. Another method is copolymerization or graft copolymerization with acrylic acid, acrylonitrile, vinyl pyridine, etc., to introduce polar groups that can be combined with dyes on the polymer macromolecules, and then directly dye with conventional methods. In the process of polypropylene production, various additives are often added to improve dyeability, light resistance and flame resistance.

- Let's take a look at the diversi

- China is directly facing the imp

- What are the core advantages of

- In November, the decline in Chin

- What is the value of Polypropyle

- The 2025 Textile Industry Discip

- The core performance advantages

- Black Friday is becoming a perfo

- Why has polypropylene high-stren

- The global trade landscape is un